Process In Manufacturing Cement And Aggregates

process in manufacturing cement and aggregates,Our company is a large-scale heavy enterprise that taking heavy mining machinery manufactory as main products and integrated with scientific research, production, and marketing. We are concentrating on producing and selling machines such as jaw crusher, cone crusher, hammer crusher, ball mill, sand maker, mobile crushing plant

Manufacturing process | Lafarge - Cement, …

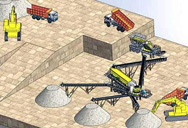

The cement manufacturing process starts from the mining of raw materials that are used in cement manufacturing, mainly limestone and clays. A limestone quarry is inside the plant area and a clays quarry is as far from the plant area as 25 km. The limestone is excavated from open cast mines after drilling and blasting and loaded onto dumpers which transport the materials and unload into hoppers ...

Manufacturing process | Lafarge in South Africa - …

From the limestone quarry to the delivery of the end product, follow every step in the cement manufacturing process. Step 1: extraction of raw materials The raw materials needed to produce cement (calcium carbonate, silica, alumina and iron ore) are generally extracted from limestone rock, chalk, clayey schist or clay.

Process Of Manufacturing Aggregates

Aug 30 2012 cement manufacturing process phase 1 raw material extraction cement uses raw materials that cover calcium silicon iron and aluminum such raw materials are limestone clay and sand limestone is for calcium it is combined with much smaller proportions of sand and clay sand clay fulfill the need of silicon iron and aluminum . More Details; Us2112380a Process Of Manufacturing Aggregates ...

aggregate mill in cement process

This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant - the kiln, the cement mill etc.. For information on materials, including reactions in the kiln, see the Clinker pages. Get Price (PDF) Cement Manufacturing - ResearchGate. Concrete. Miles Sand & Gravel Company mines aggregates …

process in manufacturing cement and aggregates

Cement: Materials and manufacturing process - GreenSpecCement Manufacturing Process 1 Extraction. Materials are extracted / quarried / recovered and transported

The Cement Manufacturing Process - Thermo …

Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated to a sintering temperature as high as 1450 °C in a cement kiln. In this process, the stone bonds of the raw materials are broken down and then they are recombined into new compounds. The result is called ...

Manufacturing process | Lafarge in South Africa - …

Water plus cement plus aggregates. The formula seems simple, but the reality of concrete manufacturing is far more complex. The development of formulas for concrete requires very advanced scientific skills. The quality of the cement and aggregates, the dosage and the proportions are just some of the variables that influence the properties of concrete.

Process In Manufacturing Cement And Aggregates

Process In Manufacturing Cement And Aggregates. The manufacturing process the manufacture of concrete is fairly simpleirst, the cement usually portland cement is preparedext, the other ingredientsaggregates such as sand or gravel, admixtures stone additives, any necessary fibers, and waterare mixed together with the cement.

The Aggregate Manufacturing Process | General …

Aggregates are important because of the qualities they possess such as strength, shape, size, texture, bulk, abrasion ability or resistance, medicinal, etc. For more than 50 years, General Kinematics has provided innovative vibratory equipment that is essential in the mining and aggregate manufacturing process. A World of Minerals

Manufacturing of Portland Cement – Process and …

The manufacture of Portland cement is a complex process and done in the following steps: grinding the raw materials, mixing them in certain proportions depending upon their purity and composition, and burning them to sintering in a kiln at a temperature of about 1350 to 1500 ⁰C. During this process, these materials partially fuse to form nodular shaped clinker by broking of stone bonds of ...

Ppt Aggregates Concrete Manufacturing Process

The Cement Manufacturing Process. The powdered cement is then mixed with water and aggregates to form concrete that is used in construction. several laboratory and online systems can be employed to ensure process control in each step of the cement manufacturing process, including clinker formation.

Manufacturing Process Of Aggregates

Manufacturing Process Of Aggregates. We are a large-scale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment. And they are mainly used to crush coarse minerals like gold and copper ore, metals like steel and iron, glass, coal, asphalt, gravel ...

Describe The Process Of Manufacturing Of …

Manufacturing Process Of Ordinary Portland Cement Opc. The mixing and grinding of the raw materials can be done either in water or in a dry condition hence two process for manufacturing of cement given below 01 dry process 02 wet process the actual methods of manufacture depend also on the hardness of the raw materials used and on. Oline Chat

Aggregates - Portland Cement Association

Aggregates are inert granular materials such as sand, gravel, or crushed stone that, along with water and portland cement, are an essential ingredient in concrete. For a good concrete mix, aggregates need to be clean, hard, strong particles free of absorbed chemicals or coatings of clay and other fine materials that could cause the deterioration of concrete.

Cement: Materials and manufacturing process

Cement Manufacturing Process 1 Extraction. Materials are extracted / quarried / recovered and transported to the cement plant. 2 Crushing and milling. The raw materials, limestone, shale, silica and iron oxice are crushed and milled into fine powders. 3 Mixing and preheating. The powders are blended (the ‘raw meal’) and preheated to around 900° C using the hot gases from the kiln. The ...

Kolkata Manufacturing Process Of Aggregates

Cement In Kolkata Manufacturers And Suppliers India. Beneficiation process in cement production christoartfairnl.Equipment beneficiation process in cement production kolkata iron ore beneficiation project in mp rotary kiln mining, crushing, grinding, beneficiation rotary kilns are commonly used for heat processing of minerals and aggregates such as lime, cement, and iron ore to achieve ...

process in manufacturing cement and aggregates

Aggregates - Portland Cement Association. Aggregates are inert granular materials such as sand gravel or crushed stone that along with water and portland cement are an essential ingredient in concrete. Get Price; Manufacturing process Lafarge in South Africa - Cement . From the lilimingne quarry to the delivery of the end product follow every ...

Quality Material Processing From Aggregates To …

Manufacturing Process | Lafarge Cement Concrete. 2020-6-8The geological nature of marine aggregates is identical to rolled sand from land quarries. Marine aggregates produce high-quality concrete, adapt well to the manufacture of innovative concretes, and are therefore an important new source of supply being explored by the Group. More Details