Power Consumption Of A Sludge Reactor In A …

Power Consumption Of A Sludge Reactor In A Gold Plant. An upflow anaerobic sludge blanket reactor uasb was invented by lettinga at early 1980s, commonly used in various anaerobic treatment techniques.Uasb can attain high biomass concentration because of its ability to reduce biomass washout.It also praised for its short hrt and higher treatment efficiency 7375.Uasb is an immobilized …

Power Consumption Of A Sludge Reactor In A …

power consumption of a sludge reactor in a gold plant. Struvite Recovery at the City of Edmontons Gold Bar… pdf of phosphate and 20% of ammonia from the sludge reject water. ... The pilot project made use of UBCs proprietary reactor design described .... summing the emissions resulting from building, operating (chemical use and power consumption) and ... the impacts of implementing a full ...

Power Consumption Of A Sludge Reactor In A …

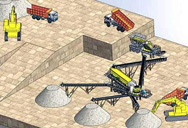

Power Consumption Of A Sludge Reactor In A Gold Plant. Processing capacity:45 - 1814 t/h . Feeding size: ≤ 314 mm . Applied materials: River pebbles, granite, dolomite, basalt, iron ore, limestone, quartz stone, diabase, iron ore, gold mine, copper mine. Get Price List

power consumption of a sludge reactor in a gold …

* Low power consumption... Reactor) plants. Ultrasonic Waste and Sludge Treatment . Energy prices and stone and sludge... 48kW individual power to various waste water treatment plants as well as ... Use of Ultrasonic Reactors in a ... Radionuclide Clean-Up at Fukushima Daiichi Nuclear Power Plant. The use of sea water for cooling during the initial emergency response at the Fukushima ...

Gold Processing Consumption-Henan Minging …

2018 1 18the consumption of cyanide during processing operations is a major economic cost in the extraction of gold from its ores, while the discharge of cyanide wastes may result in significant environmental pollution. many factors influence the levels of consumption and discharge of cyanide, including ore mineralogy and lixiviant solution chemistry..Power consumption of a sludge reactor in …

reactor in gold extraction plant - …

power consumption of a sludge reactor in a gold plant. Sequential Batch Reactor (SBR) ... The Sequencing Batch Reactor (SBR) is an activated sludge process ... Reviews: 3.9KInquire Now; Gold leaching equipment for Gold Extraction in . Gold leaching equipment is used in flotation process of gold beneficiation plant for Gold Extraction in ...

Performance Analysis of Power Generating Sludge Combustion ...

Analysis of Power Generating Sludge Combustion Plant and Comparison against Other Sludge Treatment Technologies, Applied Thermal Engineering (2009), doi: 10.1016/j.applthermaleng.2009.07.005 This is a PDF file of an unedited manuscript that has been accepted for publication. As a service to our customers we are providing this early version of the …

OPTIMIZATION OF ACTIVATED SLUDGE PROCESS THROUGH …

the energy consumption required to meet the oxygen demand required to achieve the oxidation of organic matter, which represents about 50% of the energy consumption of the plant. We present our analysis and conclusions of the measurements of the physicochemical parameters obtained during the operation and maintenance of the SPA II plant located in San Juan del Río Querétaro, Mexico, where ...

WWTP Energy Management Solutions and Case Studies

Power Factor Run Hours per Day 30 0.5 95% 18.0 14.25 7,952 Miscellaneous Receptacles KW per Sq. Ft. Sq. Ft. Run Hours per Day 1.5 32000 24.0 48.00 35,712 Totals 186,276 Total Baseline Electricity Loads 1,567,237 Detailed mapping of power systems, MCCs, etc. Static energy model to account for unit process energy consumption Model calibration through

Copper Ore Plant Efficient Thickener Low …

Copper Ore Plant Efficient Thickener Low Consumption. Power consumption of a sludge reactor in a gold plantower consumption of a sludge reactor in a gold planthe sludge developed in the reactor was flocculent and did not form compact o produce electricity that supplies 4050 of the plant electricity requirementsydrogencyanide gas is liberated, and a metallic gold slime is produced.

Conventional Activated Sludge Process - an …

The energy consumption for municipal wastewater treatment using the ... The MBBR system takes higher shock loads without reducing the plant performance because of the large quantity of active biomass available inside the reactor. The SBR is a fill-and-draw activated sludge system for wastewater treatment. In this system, wastewater is added to a single “batch” reactor, treated to remove ...

Life cycle assessment of sewage sludge co …

LCA of sludge co-incineration in coal-fired power plants was studied. • Sewage sludge co-incineration presents higher economic benefits. • The efficiency of net coal consumption is a key to reduce environmental impact. • Increasing incinerated ash reuse capacity can reduce environmental burden. • Decreasing water content rate of sludge can increase overall environmental burden ...

Sludge Treatment at U.K. Facility Turns Waste Into …

The sludge recycling center runs on enough human waste to power 25,000 homes. It was built by Black & Veatch for United Utilities Group Plc, Britain’s largest publicly traded water company. Awarded IChemE’s international prize as “the most innovative green-energy scheme on Earth,” the facility renders waste into what engineers call “black gold.”

COD capture: a feasible option towards energy …

Although the activated sludge process, one of the most remarkable engineering inventions in the 20th century, has made significant contribution to wastewater reclamation in the past 100 years, its ...

Cost estimation and economical evaluation of three ...

activated sludge (CAS), extended aeration activated sludge (EAAS), and sequencing batch reactor (SBR) processes for a wastewater treatment plant in Tehran city were proposed and the total project construction, operation labor, main-tenance, material, chemical, energy and amortization costs of these WWTPs were calculated and compared. Besides, effect of mixed liquor suspended solid (MLSS ...

APPENDIX 4-T HDS WATER TREATMENT PLANT DESIGN AND …

Rescan Environmental Services has reviewed and updated the SGS-CEMI KSM High Density Sludge Water Treatment Plant design and report to treat a wide range of acidic contact water flow rate during the year. The flow rate is projected to be as low as 0.1 m3/s during December to March then increasing to match natural stream flows through spring to a maximum of 7.5 m3/s in the summer months. The ...

Activated sludge - Wikipedia

Activated sludge plants are wholly dependent on an electrical supply to power the aerators to transfer settled solids back to the aeration tank inlet, and in many case to pump waste sludge and final. In some works untreated sewage is lifted by pumps to the head-works to provide sufficient fall through the works to enable a satisfactory discharge head for the final effluent. Alternative ...

Anaerobic treatment of municipal wastewater in UASB-reactors

reactor and the “3-phase-separation” of sludge, gas and water (see also chapters 8.2 and 8.3). While the sludge should remain in the reactor, the produced gas is collected before the purified water leaves the reactor. For a simple process flow scheme, see Figure 1 below:

(PDF) Optimal design of an activated sludge plant ...

The design procedure of an activated sludge plant consisting of an activated sludge reactor and settling tank has been theoretically analyzed assuming that (1) the Monod equation completely ...