Mill (grinding) - Wikipedia

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many processes. There are many different types of mills and many types of materials processed in them.

Ball Mill Operation -Grinding Circuit Startup & Shutdown ...

Normal Ball Mill and Grinding Circuit Operation After the grinding circuit has been brought up to normal operating conditions, the operator must monitor the various process variables and alarms. Most of …

Grinding technology and mill operations | FLSmidth

Improving knowledge of grinding technology and mill operations to operate, optimise and troubleshoot ball mill and vertical roller mill grinding installations. Ball mills and vertical roller …

How to use the grinding mill better?

Jul 06, 2020 · The emergence of the grinding mill is a major technical breakthrough in the milling industry. Its grinding operation makes the grinding of some difficult materials come true, which …

Grinding Operation - an overview | ScienceDirect Topics

Grinding Operation. Grinding operations are divided into roughing and finishing, which differ, e.g. in terms of grit size [59, 63, 71, 90, 91, 94, 95]. From: Surface Treatment in Bonding Technology, 2019. …

History—Now and Then: Grist for the Mill: An Operational Guide

Oct 31, 2010 · A gristmill exists to grind a variety of grains into flour, meal, or feedstock. While some mills derived their power from the wind, the water-powered mill ground the largest quantity of stone in the eighteenth and nineteenth centuries. Wind could not generate the horsepower available to water-powered operations.

operating grinding mill

Analysis of ball mill grinding operation using mill … Analysis of a large amount of batch ball mill grinding data available in the literature has shown that the values of the power specific absolute rate of grinding of the topmost size fraction, S *, and the power specific absolute rate of production of −100 mesh fines, F *, are not independent of the mill operating conditions and mill ...

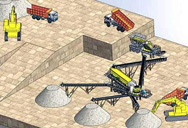

Grinding mills - for mining and minerals processing - liming

Every mining operation has a unique grinding process. liming has experience of over 8,000 grinding mills globally, including manufacturing and delivering the largest SAG/AG mills in the world. Our …

Installation, Operation and Maintenance of the Airflex ...

protection for grinding mill drive systems and has been developed to prevent costly damage to the motor, clutch, or other grinding mill drivetrain components. This system con-tinuously monitors clutch performance during start-up and running operations…

Ball Mill: Operating principles, components, Uses ...

Jul 05, 2020 · Ball mills grind material by impact and attrition. The degree of milling in a ball mill is influenced by; a. Residence time of the material in the mill chamber. b. The size, density, and number of the balls. c. The nature of the balls (hardness of the grinding …

Grinding mill services - liming

Grinding mill liner replacement Liner replacement is a major maintenance activity for your grinding circuit. A reline can make-or-break your shutdown, either saving you valuable time or costing you …