large crushing ratio fine cone crusher

large crushing ratio fine cone crusher in productivity and high reduction ratio from large primary jaw crusher six large cone crushers for its. large crushing ratio fine cone crusher. high quality and large crushing ratio jaw crusher - , large crushing ratio fine cone crusher by possesses advanced world level quality high reduction ratio From .

large crushing ratio fine cone crusher - benb …

Cone crusher is an advanced hydraulic crusher with high power, large crushing ratio, and high productivity. Generally, it uses as a secondary crusher to break medium-hard materials, and use as fine crushers in artificial sand making process plants and quarry plant.

cone crusher for fine crushing - retraite-academie.nl

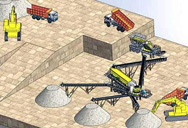

Cone crushing machine further broke the stone to below 10 cm. Large cone crushers (gyratory crushers) also can as head crushers. Fine jaw crusher also can as a two-stage crusher, crushing stone to cm grade particle size range. There are five differences from jaw crusher vs cone crusher. Crushing ...

Large Crushing Ratio Fine Cone Crusher - nizzisara.it

The optimal cone crusher for crushing plant. The cone crusher is widely used in many sectors such as mining, smelting, building materials, roads, railways, water conservancy, and stone industries.The cone stone crusher has a large crushing ratio, high efficiency, low …

large crushing ratio fine cone crusher - …

large crushing ratio fine cone crusher. Gravel - Wikipedia. Geological formation. Large gravel deposits are a common geological feature, being formed as a result of the weathering and erosion of rocks.

Large Crushing Ratio Fine Cone Crusher

Large Crushing Ratio Fine Cone Crusher . Prompt : Caesar is a famous mining equipment manufacturer well-known both at home and abroad, major in producing stone crushing equipment, mineral separation equipment, limestone grinding equipment, etc.

Jaw Crusher VS Cone Crusher | Advantages and …

Jaw crusher breaks the rock to 10 ~ 30 cm size. Cone crushing machine further broke the stone to below 10 cm. Large cone crushers (gyratory crushers) also can as head crushers. Fine jaw crusher also can as a two-stage crusher, crushing stone to cm grade particle size range. There are five differences from jaw crusher vs cone crusher. Crushing ...

Cone Crusher For Sale - Big Crushing Ratio And …

Cone crusher for sale is a kind of crusher machine. Because of its high crushing ratio, high efficiency, low energy consumption, uniform crushed particle size, cone crusher machine is usually used for medium crushing and fine crushing.

The optimal cone crusher for crushing plant

The cone crusher is widely used in many industries such as mining, smelting, building materials, roads, railways, water conservancy, and stone industries.The cone stone crusher has a large crushing ratio, high efficiency, low energy consumption and uniform product size. It is suitable for medium and fine and rocks crushing.

Cone Crushers - Mineral Processing & Metallurgy

Cone crushers are used in AG and SAG grinding circuits to increase tonnage by effectively dealing with any pebble (critical size) build-up problem. Normally, heavy duty short-head crushers are employed to crush pebbles. Power and crusher cavity level are the key variables for monitoring and controlling the crusher operation.

large crushing ratio fine cone crusher - …

Cone crusher crusher is an important crushing machinery, with a large crushing ratio, high output, less power consumption, fine and uniform product granularity, suitable for crushing hard and high hard ore and other special, is widely used in metallurgy, mining, coal, water conservancy, construction and other industrial fields."Flying car" is unique to the cone crusher crusher is also a common ...

Crusher Reduction Ratio - Mineral Processing & …

I have mentioned the fact that, as the % of voids in the crushing chamber decreases, the production of fines by attrition increases. This is like saying that, as the Crusher Reduction Ratio in any given crusher is increased, the % of fines in the product will increase, even though the discharge setting remains unchanged. Both of these statements are true, but the degree to which the product is ...

crushing function of cone crusher - froggit.co.za

Cone Crusher - Crushing Equipment - Products - … Luoyang Dahua cone crusher has hydraulic cone crusher and fine cone crusher machine. It can be used for crushing hard materials, uses laminating crushing principle, large offset, automatic iron protection function, the crushed particle are in good shape. Get Price

Cone Crusher - an overview | ScienceDirect Topics

Cone crushers were originally designed and developed by Symons around 1920 and therefore are often described as Symons cone crushers. As the mechanisms of crushing in these crushers are similar to gyratory crushers their designs are similar, but in this case the spindle is supported at the bottom of the gyrating cone instead of being suspended as in larger gyratory crushers.

Crushers - All crusher types for your reduction …

Fine crushing with cone crushers. Due to their design, ... Reduction ratio must be limited to 3 (-4). Recommended max feed size is 50 mm. ... from high-capacity primary crushers for large limestone quarries to specially designed machines for the crushing of materials such as slag.

Big Crusher Mobile Cone Rock Crusher | Crusher …

crushers of large crushing customer case – Ball mill for sale … Crushing Large Rock Jaw Crushers … (portable crushing plant),cone crusher,mobile crushing station and Mobile Crusher for sale in China CGM.From this page,if you are …

14 Cone Crusher Common Problems And How To …

Cone crusher has high crushing ratio, high efficiency, low energy consumption, uniform product size, suitable for medium crushing and fine crushing of various ores and rocks. In the cone crusher working process will encounter a variety of problems, So, we provides 14 common fault causes and solutions!

How to Select Impact Crusher and Cone Crusher?

As a high-power, large crushing ratio, high productivity, high reliability cone crusher mainframe, Camelway cone crushing mainframe is widely used in medium and fine crushing of high hardness materials, especially suitable for ultra-fine crushing and hard rock, ore, slag, refractory materials and so …

Cone Crushers | McLanahan

A general rule of thumb for applying Cone Crushers is the reduction ratio. A crusher with coarse style liners would typically have a 6:1 reduction ratio. Thus, with a 3⁄4” closed side setting, the maximum feed would be 6 x 3⁄4 or 4.5 inches. Reduction ratios of 8:1 may be possible in certain coarse crushing …

liming® HP300™ cone crusher - liming

liming® HP300™ cone crusher produces finer products by limiting crushing stages, which lowers your investment cost and saves energy. This is achieved through a combination of optimized speed, large throw, crushing chamber design and increased crushing force. The efficient crushing action of liming® HP300™ cone crusher gives it the ...