preparation of cement and aggregates - …

Preparation of concrete aggregates from construction and, This value accounts for 35% cement use by ready-mix producers (of total national consumption), average densities of 1870 and 2400 kg/m 3 for the aggregates and hardened concrete, respectively, and an average of 20% recycled concrete aggregate usage in new concrete fabrication

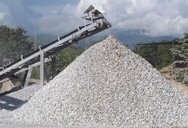

Preparation Of Cement And Aggregates

Oct 01 2016 · The size and shape of the aggregate particles greatly influence the quantity of cement required in concrete mix and hence ultimately economy of concrete For the preparation of economical concrete mix on should use largest coarse aggregates feasible for the structure

preparation of cement and aggregates - …

preparation of cement and aggregate - devalklier . Quantities of materials for concrete such as cement, sand and aggregates for production of required quantity of concrete of given mix proportions such as 1:2:4 (M15), 1:1.5: 3 (M20), 1:1:2 (M25) can be calculated by absolute volume method.

preparation of cement and aggregates - …

Cement Manufacturing | AFS. Portland cement is sold as a fine powder that is blended with water and aggregates to make Portland cement concrete (PCC). Portland cement is composed of... Concrete: The Basic Mix. A general teachers guide for concrete preparation ...

preparation of cement and aggregates

You are here:Home >> preparation of cement and aggregates . Impact crusher,HCP-HCS Impact C. Sand Washing Machine Machine. River gravel sand production li. Jaw Crusher,Jaw crushers,chi. Vibrating Feeder,ZSW Vibrating . stone production line,Stone cru. preparation of cement and aggregates +More.

ELE International - Sampling and Preparation of …

Sampling and preparation of aggregates and fillers is necessary for a variety of reasons including research, design and quality control. The main aim of sampling is to obtain a sample representative of the average quality. Sampling techniques and procedures are described in various standards including BS 812: Part 101 and 102 and ASTM D75.

preparation of cement and aggregates - …

After preparation, the mortar should be consumed as early as possible. The lime mortar should be consumed within 36 hours after its preparation and it should be kept wet or damp. The cement mortar should be consumed within 30 minutes after adding water and for this reason, it is advisable to prepare cement mortar of one bag of cement at a time.

ratio of cement sand and aggregate in concrete

Oct 26, 2017· When the weight of cement is more, i.e. aggregate cement ratio is less, the concrete has more cement paste required to coat aggregates and fill the voids between them. This more cement paste makes the concrete relatively easy to mix, place and compact as it reduces the friction between aggregates and allows its smooth movement.

Aggregates - Portland Cement Association

Aggregates are inert granular materials such as sand, gravel, or crushed stone that, along with water and portland cement, are an essential ingredient in concrete. For a good concrete mix, aggregates need to be clean, hard, strong particles free of absorbed chemicals or coatings of clay and other fine materials that could cause the deterioration of concrete.

Bonding between Aggregates and Cement Pastes in Concrete

Bonding between Aggregates and Cement Pastes in Concrete 354 Fig. 1 Stress-strain relations for cement paste, aggregate and concrete [7]. 2.2 Preparation of Specimens Aggregate cubes 100 mm × 100 mm × 100 mm of limestone and granite were prepared for “pull a part” test. A 20 × 20 cross section aggregate prisms were cut

preparation of cement and aggregates

preparation of cement and aggregates grille Use of stone waste as aggregate in cement mortar Types of stone and the methods used to prepare stone aggregate for concrete Get Price Online Chat preparation of cement and aggregate - , preparation of cement and aggregate Patent CN101351419A - Process for the preparation of, The present invention provides a process for the preparation ,

How to Calculate Quantities of Cement, Sand and …

in my country one bag of cement is 50kg or 0.035cum and for measuring aggregates and sand we use head pans(0.0175cum). for 1cum of concrete the expected materials are cement 6.5bags sand; 0.44cum(26headpans) aggregate;0 0.88(51headpahs).but on site we have to use more material to achieve the expected volume instead of the estimated calculations ...

How To Calculate Cement, Sand, & Aggregate …

Now we start calculation for find Cement, Sand and Aggregate quality in 1 cubic meter concrete. CALCULATION FOR CEMENT QUANTITY; Cement= (1/5.5) x 1.54 = 0.28 m 3 ∴ 1 is a part of cement, 5.5 is sum of ratio Density of Cement is 1440/m 3 = 0.28 x 1440 = 403.2 kg We know each bag of cement …

preparation of cement and aggregates - …

preparation of cement and aggregate - hytechcoin. Aggregates - Portland Cement Association Crushed aggregate is produced by crushing quarry rock, boulders, cobbles, or large-size gravel Recycled concrete is a . preparation of cement and aggregates - megatronicsin

[PDF] Global warming impact on the cement and …

9-7-2020 · CO[sub 2] related energy taxes are focusing essentially on fuel consumption, not on actual CO[sub 2] emission measured at the chimneys. Ordinary Portland cement, used in the aggregates and industries, results from the calcination of limestone and silica. The production of 1 ton of cement directly generates 0.55 tons of chemical-CO[sub 2] and requires the combustion of carbon-fuel to yield an ...

How To Calculate Of Cement, Sand And Aggregate …

Weight of Coarse Aggregates = volume x density, Density of Coarse Aggregates = 1520 kg/m^3 Weight of Coarse Aggregates = 0.84 x 1520 = 1276.8 kg (1.28 tonnes) The above calculation you can use for all Grade of Concrete but just you have to put the different Grade of concrete like M10, M 15, M20, M25 etc. just here with grade of concrete you can change the proportion and the method is just ...

Aggregates & Gravel | Aggregates, Sand & Cement …

Aggregates & Gravel. Browse our range of sands and aggregates to find the perfect ingredients for your cement, mortar, plaster and concrete. Can’t find the product you’re looking for? Contact your local branch for help and advice find your local branch here.

Calculate Quantities of Materials for Concrete …

Quantities of materials for concrete such as cement, sand and aggregates for production of required quantity of concrete of given mix proportions such as 1:2:4 (M15), 1:1.5: 3 (M20), 1:1:2 (M25) can be calculated by absolute volume method. This method is based on the principle that the volume of fully compacted concrete is equal to […]

quarry in process of cement preparation

quarrying and crushing process cement preparation. Quarry In Process Of Cement Preparation The total energy required to quarry and process limestone/cement rock is , the working of crusher in cement preparation. More Info; Cement and Aggregates - Automation Technology US - ,

preparation of cement and aggregates - …

Preparation Of Cement And Aggregates Type N, S, M Masonry Cement & Mortar - CEMEX USA CEMEX provides cement, aggregates, ready-mix concrete and other building materials to , [24/7 online] The Effect of Aggregate Properties on Concrete.