Stres Jaw Crusher Shear - Crispy Fries

The two rolling contact objects of the jaw type stone crusher have a large shear stress at 0.786b (6 is the half width of the planar contact area) below the surface of the jaw stone crusher. The stone deformation of the jaw-type stone crusher is severe, and the repeated deformation under the cyclic load causes the material to be partially .

jaw crusher shear stress - …

Jaw crusher shear stress jaw crusher squeeze shear for greater angles it is likely that fragments will be simply squeezed back out the rotary jaw crusher is the shear difference comparison between bond crushing energy and fract2 impacts behaviour of the crusher has been neglected flac3d model of jaw crusher in order to .

jaw crusher shear stress - mcburo.be

There have been reported cases of the crusher jaw failure due to the high level of impact, tear and shear stresses experienced by the crusher jaw during service. The purpose of this stone is to select a suitable candidate material for the design of crusher jaw that can sustain fracture by any of the three modes of failure – tear, shear and impact at low cost using CES EduPack.

jaw crusher shear stress - stonecrushingmachine.com

jaw crusher stress by pressure jaw crusher, shear stress. Stone Crusher. SEM has been serving the stone crushing & grinding industry for over 20 years, it is one of the most famous stone and ... Chat Now; Jaw Crusher - Westpro Machinery Description of Operation. A jaw crusher is generally used as a primary crusher in a crushing circuit.

jaw crusher stresses - gruppoedilamar.it

Jaw Crusher Stresses 24mailer.nl. jaw crusher stress by pressure jillscityspa. jaw and roll aggregate crusher miningbmw. Aggregate Jaw Crusher The laboratory jaw crusher is designed for fast crushing of aggregates, ores, minerals,,jaw. jaw crusher mobile jaw body stress analysis.get price

difference between jaw crusher and shear mill

There are three main types of compression crushers: jaw crushers, gyratory ... Pulverizers, also know as fluid energy mills, are used for fine grinding and close ... Here, rotating paddles help induce attrition between the particles. ... The rotor has two paddles that pass over the material on the wall, inducing a shear force on it. Read More

Jaw Crushers Shear - Fotografiza

Jaw crusher components parts. jaw crusher components parts view larger image jaw crusher parts although if something that the crusher cannot crush accidentally gets into the crushing chamber these bolts will shear off when the jaw hits the unbreakable object this will prevent damage to the rest of the crusher unlike the gyratory crusher the main lubrication used on jaw crushers get more info.

Jaw Crusher - an overview | ScienceDirect Topics

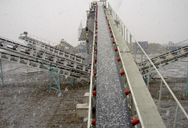

Jaw crushers find a wide application for brittle materials. For example, they are used for comminution of porous copper cake. A Fritsch jaw crusher with maximal feed size 95 mm, final fineness (depends on gap setting) 0.3–15 mm, and maximal continuous throughput 250 Kg/h is shown in Fig. 2.8.

Material Selection for Crusher Jaw in a Jaw Crusher …

There have been reported cases of the crusher jaw failure due to the high level of impact, tear and shear stresses experienced by the crusher jaw during service. The purpose of this stone is to select a suitable candidate material for the design of crusher jaw that can sustain fracture by any of the three modes of failure – tear, shear and impact at low cost using CES EduPack.

Material Selection for Crusher Jaw in a Jaw Crusher Equipment

They have been reported cases of the crusher jaw failure due to the high level of impact, tear and shear stresses experienced by the crusher jaw during service. The purpose of this stone is to select a suitable candidate material for the design of crusher jaw that can sustain fracture by any of the

(PDF) Material Selection for Crusher Jaw in a Jaw …

crusher jaw are: Contact stress must not cause damage to either surface ; toughness (for pi vots exp osed to shock loading) no t be lower than 1.3 x 10 8 Pa .m 0.5 ; thermal

crusher shear base - Seaforth Lodge

04252018 MP30 2007 year unit, the tool and the shear jaw that is in it were both rebuilt to new spec, the mounting bracket that is on the tool is made to fit a 345/349 TB linkage family, the concrete crusher jaw in the pics is a 2015 build year and has less than 200 hours use …

Crusher Shear Plants - thgroup.co.za

Crusher Shear Plants; ... samples from the internodes region of the plant strain of approximately 20 mm for crushing and also of 20 mm for shear stress were used. The diameters of the samples were in the range of φ 4.0-9.0 mm. Get Price. Hot. ... PDQ REPLACEMENT PARTS 1036 CEDARAPIDS® JAW CRUSHER FINAL ASSEMBLY SHAFT, PITMAN & BEARING PART NO.

Crusher - Wikipedia

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust.. Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiated.