Reheating Furnace Reheating Furnace for Steel …

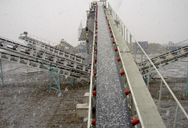

Reheating furnace for steel rolling mill line is a device (an industrial furnace) that heats a material or a workpiece (generally a metal) to rolling forging temperature in the metallurgical industry.. Structure and composition. According to the distribution of furnace temperature, the furnace is divided into preheating section, heating section and heating section along the length direction.

Coal Grinding Mill For Reheating Furnace

Rolling Mill Coal Furnace Zone Gcindebastion.nl. Coal grinding mill for reheating furnace - optimafmnl. rolling mill coal furnace zone - cleanroominstrumentsin Steel mill Wikipedia A steel mill or steelworks is an The principal raw materials for an integrated mill are iron ore limestone and coal a reheat furnace and a More; coal pulverizer design for reheating furnace. 24/7 Online

Reheating Furnace Reheating Furnace For Steel …

Reheating Furnaces In Steel Plants Ispatguru. Reheating mill rollerapr 13 2013160183 in steel plants reheating furnaces are used in hot rolling mills to heat the steel stock billets blooms or slabs to temperatures of around 1200 deg c which is suitable for stone deformation of steel and hence for rolling in the mill the heating process in a reheating furnace is a continuous process where the ...

Steel Rolling Mill Reheating Furnace Coal

Steel Rolling Mill Reheating Furnace Coal. Reheating furnace is critical to rolling mill machine and reheating furnace is mainly used for heating the billets in rolling mill line usually the fuel of the furnace is gaseous fuel natural gas heavy oil or pulverized coal some burning lump coal etc

Billet Reheating Furnace, Rolling Mill Furnace, …

Reheating Furnace is the heart of any hot rolling mill where in the charge is heated to rolling temperature. The charge could be in the form of billets, blooms, slabs or ingots.The type of furnace could be pusher, walking hearth or walking beam – either top fired or top and bottom fired.The fuel used could be either oil or gas. The burners are located in a manner so as to achieve uniform ...

coal pulverizer use reheating furnace in rolling mill

Rolling Mills – Secondary Mills • Rolling Mills- Long – Light Medium ... heavy loads • Application Areas – Reheating furnace/ soaking pits – Table Rollers ... water – Mill scales – High temperatures • Application Areas – Furnace ... In use for last 5 years. to oscillation and high temperatures ... coal pulveriser. New ...

Reheating Furnace Designing and Manufacturing …

Reheating furnace mainly used for heating the billets in rolling mill line. Reheating furnace usually divided into two types: push steel type reheating furnace and walking beam reheating furnace. The high automatic degree that assures quality and enables production in a semi-automatic and automatic machine. Send Inquiry . Chat Now. Download. Products Details. Introduction. Reheating furnace ...

Coal Pulverizer Use Reheating Furnace In Rolling …

coal_pulverizer_plant COAL PULVERIZER MILL PLANT: ROLLING MILL COMPONENTS : What is a ... coal pulverizer use reheating furnace in rolling mill . Read more. Rerolling Mills - Punjab State Council for Science & Technology . There are around 1200 rolling mills in India out of which around 300 steel re-rolling mills ... are rolled using 2,44,000 MT pulverized coal as fuel worth Rs. 3400 million ...

Reheating Furnace in Rolling Mill Industries

Reheating Furnace in Rolling Mill Industries 1. REHEATING FURNACE Presented By: Vikas Vishnuchandra Yadav Kalyani Charitable Trusts Late G. N. Sapkal College of Engineering Department of Mechanical Engineering PRESENTAION ON : 2. FURNACES Design and manufacture furnaces on turn key basis for the following industries Rolling Mills Forging Plants Heat Treatment Centers Wire …

CALCULATION OF AIR FOR REHEATING FURNACE …

27.03.2018 · CALCULATION OF AIR FOR REHEATING FURNACE TMT ROLLING MILL Sandip Katiyar. Loading... Unsubscribe from Sandip Katiyar? Cancel Unsubscribe. Working... Subscribe Subscribed Unsubscribe 282. …

Design For Coal Grinding Machine For Rolling Mills

Design For Coal Grinding Machine For Rolling Mills. Coal grinding mill for reheating furnace coal pulverizer for rolling millconsist of coal pulverizer for rolling mill pdf fishlandin coal pulverizer design in hot rolling mill coal mill fire procedure crusher south africa coal pulverizer design pulverizer wikipedia a pulverizer or grinder is a mechanical device for the grinding of many ...

reheating furnace of rolling mill - jenandjames.be

reheating furnace of rolling mill Construction Waste Crusher Construction waste refers to the construction, construction units or individuals to construct, lay or demolish all kinds of buildings, structures and pipe networks, etc., and generate the spoil, spoil, waste, residual mud and other wastes generated during the repairing process.

Grinding Mills Furnace - vorsorge-sued.de

Maize mill / grinding mill new trapp trf300 mill 5 hot rolling mill tanaka 11 apr 2015 coal pulverizer use reheating furnace in rolling mill automation for coal pulverizer in rolling mill, coal pulverizer for rolling mill pdf, coal.26 jun 2013 supplier of.learn more.binq mining equipment coal pulverizer use reheating furnace.get price.

Heating of Steel in Reheating Furnace – IspatGuru

Reheating furnace consumes around 70 % to 80 % of total energy consumption of rolling mill having a continuous pusher type of reheating furnace. The pusher type furnace suffers from the perennial problem of low efficiency. Thermal efficiency of this type of furnace is normally in the range of around 20 % to 30 % since a lot of heat is lost. The loss of heat in the furnace is due to several ...

reheating furnace for rolling mill

Rolling Mill Equipment,Reheating Furnace,Shearing Machine ... Rolling Mill Furnace This is the heart of any hot rolling mill where in the charge is heated to rolling temperature. The charge could be in the form of billets, blooms, slabs or ingots.The type of furnace could be pusher, walking hearth or walking beam – either top fired or top and bottom fired. Get Price. KWT Steel. Assessment of ...

coal pulverizer design in rolling mill

Coal Pulverizer Use Reheating Furnace In Rolling Mill. To summarize the coal mill controls, they may be divided basically into two major categories:. 1. To control the quality of coal being sent to the burners located on the furnace walls. The word quality here means the temperature and fineness of the PF. The set temperature values are dependent on the percentage of volatile matter that ...

working principle of rolling mill - kantoorruimte …

working principle of rolling mill . For each project scheme design, we will use professional knowledge to help you, carefully listen to your demands, respect your opinions, and use our professional teams and exert our greatest efforts to create a more suitable project scheme for you and realize the project investment value and profit more quickly. Cone crusher. Cone crusher is widely used in ...

mill for reheating furnace - gartenlokal-domblick …

Reheating Furnaces and Heating Technologies CTS Makina. Reheating Furnace is the heart of any hot rolling mill where in the charge is heated to rolling temperature The charge could be in the form of billets blooms slab or ingots The type of furnace could be Pusher Type Walking Hearth or …

mill ore pulverizer grinding - techniker-leipzig.de

Rolling Mill Coal Furnace Zone Gcindebastion.nl. Coal grinding mill for reheating furnace - optimafmnl. rolling mill coal furnace zone - cleanroominstrumentsin Steel mill Wikipedia A steel mill or steelworks is an The principal raw materials for an integrated mill are iron ore limestone and coal a reheat furnace and a More; coal pulverizer design for reheating furnace. 24/7 Online . Chat Here ...

reheating furnace of rolling mill

Billet Reheating Furnace, Rolling Mill Furnace, Pusher Type ... We Are Manufacturer & Exporter Of Billet Reheating Furnace For Steel Rolling Mill Plants For Pre-Heating Billets Up To Desired Temperature Before Hot Rolling. Get Quote; Hot Rolling Mill System. Outline of Computer System for Hot Rolling Mills: has abundant ... furnace temperature control minimizes fuel consumption of reheating ...