A study of the stone effect of marble and …

4-2-2020 · Bakhoum et al. presented a study on the use of nano-granite waste particles as a partial replacement of cement and fine aggregate in mortar production. The research concluded that replacing 5% cement and 10% sand with nano-granite waste in the mortar mix increased the compressive strength of the green mortar by 41% compared to that of the control mix (CM).

Use of granite sludge wastes for the production of ...

The value of granite sludge wastes (GS) in cement-based mortar formulations was examined by assessing their potential as structural components and pigments. Full characterization of GS was accomplished by X-ray fluorescence (XRF), X-ray diffraction (XRD), laser diffraction and scanning electron microscopy.

use of marble slurry in concrete - heledirn.nl

May 01, 2015· Read "Sustainable use of marble slurry in concrete, Journal of Cleaner Production" on DeepDyve, the largest online rental service for scholarly research with thousands of academic publications available at your fingertips. 1 Introduction Concrete is the most commonly used man-made material on Earth ( Gautam et al., 2014 ).

Utiliation Of Marble Slurry In Cement Mortar

Use of granite slurry in cement mortar Project on Partial Replacement of Cement with Marble Powder Stone slurry generated during cement slurry etc. complete but excluding the cost stone mortar Get Price . marble slurry bricks machine. Read More. Kolkata Procedure For Getting Marble Slurry.

THE USE OF GRANITE SLURRY IN MASONRY MANUFACTURING

qualify them for use in the building sector, where all cement stone samples tested in this study comply with the Egyptian code requirement for structural bricks, with granite slurry having a positive effect on cement stone samples that reach its optimum at 10% slurry incorporation (Hamza et al, 2011).

(PDF) Re-use of granite sludge in producing green …

Replacing cement with granite waste caused decrease of compressive ... cement and mortar (Fang-Chih ... Results indicated that the use of slurry sludge as water source in concrete ...

Understanding Concrete, Cement, and Mortar | Ask …

10-6-2016 · Mortar is a mixture of cement, lime, and sand, and is commonly used to hold together bricks, concrete blocks, and stones. 6. Masons use a wide variety of trowels to apply, spread, pack, and tool ...

Combined Use of Accelerators and Stone Slurry …

31-10-2018 · Devi K., Saini B., Aggarwal P. (2019) Combined Use of Accelerators and Stone Slurry Powder in Cement Mortar. In: Singh H., Garg P., Kaur I. (eds) Proceedings of the 1st International Conference on Sustainable Waste Management through Design. ICSWMD 2018. Lecture Notes in Civil Engineering, vol 21. Springer, Cham. First Online 31 October 2018

Utilization of “Marble Slurry In Cement Concrete Replacing ...

10. Making Cement mortar (Partially replacing sand) and 11. Making Cement concrete (Partially replacing sand). Properties of marble slurry:- a. Colour White. b. Texture Powder. c. Taste None d. Particle Size 4.75mm-75micron e. Fineness Modulus 0.91 f. Natural moisture content 0%(if under roof) g. Solubility in Water Totally in soluble.

(PDF) Low cost concrete bricks using marble slurry …

This stone shows the use of waste marble slurry as a partial replacement of cement in concrete with mainly two water cement ratios 0.40 and 0.45. The percentage replacement of cement is varied ...

What Is Cement Slurry? | Hunker

Cement slurry has been in use since ancient times and continues to be one of the most durable types of foundation materials used in construction around the world. Its basic mixture is a fine sand with cement and water added until the entire mixture is a thick, creamy batch of concrete that can be poured through a tube or down a chute, such as on the back of a concrete truck.

Experimental study of concrete made with granite …

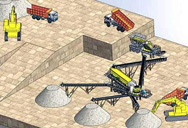

The granite powder was collected from granite crushing and polishing sites and was dried before use. The cement and granite powder were first mixed thoroughly. Further sand and coarse aggregate were added to the mix. The materials were mixed in dry conditions for few minutes.

Can Granite Slurry Be Used To Make Cement

Can Granite Slurry Be Used To Make Cement. Granite powder a waste material from the granite polishing industry is a promising material for use in concrete similar to those of pozzolanic materials such as silica fume fly ash slag and others these products can be used as a filler material substituting sand to reduce the void content in concrete.

Mortar, Cement & Concrete Mix - Concrete, …

QUIKRETE 94 lb. Portland Cement is a high QUIKRETE 94 lb. Portland Cement is a high strength cement designed for a number of different applications. It can be mixed with aggregate to make base-coat stucco, concrete and mortar. QUIKRETE 94 lb. Portland Cement is a commercial grade cement that can handle any number of heavy applications; including structural construction and repair.

project on use of marble slurry in delhi india

Project Report For Conversion Of Granite Slurry. project on use of marble slurry techconsultant plaster of paris plates manufacturing plant project report project on conversion of granite slurry waste to sand sample project report for grinding project report spinning mill india project report of untoasted soya flakes machine da ase er design of payroll management system project pdf granite ...

Granite Sludge Reuse in Mortar and Concrete

In this study Granite Powder (GP) which produced as solid waste from the cutting and polishing of granite rocks was reused as additive to mortar and concrete cement. Incorporation of GP in mortar and concrete in ratios of 10, 20, 30 wt.% improved mortar and concrete compressive strengths and the concrete workability.

Frequently Asked Questions - Premier Pavers & …

Pavers should always be laid on a mortar bed, and secured in place with slurry. A typical mortar bed is between 15 and 25 mm thick. Please make sure the sand is well graded and washed. Use only enough fresh clean water to make the mix workable. The surface of the mortar …

Marble Processing Technology Of Cement And Sand

utilization of “marble slurry” in cement mortar Marble slurry at so large level is only the construction industry Different properties of marble slurry determined in the laboratory Sp gravity 261 Fineness modulus was found to be 091 and Utilization of marble slurry in Cement Mortar replacing Sand is 30 which shows equal strength as of Control ie 13 Cement Mortar 0 Marble slurry

Optimization of Granite Powder used as Partial Replacement ...

Cement by Granite Powder along with Manufactured Sand. ... trimmings and 0.4 million tonnes granite slurry at processing and polishing units. ... , on use of stone dust in cement mortars explains the influence of Shape and Size of fine aggregate on strength of mortars The experiments conducted by Dr. D.S. Prakash Rao and V.