Amalgamation Process of Gold

The use of direct amalgamation following stamps or primary mills and the use of barrel amalgamation for treating jig and corduroy concentrates. Precipitation of gold and silver on zinc dust or on zinc shavings is fully treated, from the clarification and de-aeration of cyanide solutions to the cleanup and melting of the bullion. The use of aluminum dust, sodium sulphide, and charcoal as precipitants receives attention.

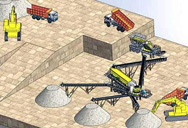

Portable Gold Processing Plant

Portable Gold Amalgamation Plant Free milling gold and silver ores are efficiently and economically treated in Amalgamation Mills. These mills are often used in the early stages of development of free milling gold properties to recover the main portion of the gold with a simple, inexpensive flowsheet.

Gold Amalgamation Plant - MC World.INC - 34Jap

Gold Amalgamation Plant - MC World.INC Amalgamation Process of Gold - Mineral Processing MetallurgyThe use of direct amalgamation following stamps or primary mills and the use of barrel amalgamation Large-scale crushing & screening & milling plants. Offer efficient, cost …

gold amalgamation plant - populareducation.co.za

Mercury hazards from gold mining to humans, plants, and animals. Mercury contamination of the environment from historical and ongoing mining practices that rely on mercury amalgamation for gold extraction is widespread. Gold Mining operations using cyanide and amalgamation

Extraction Of Gold By Amalgamation Plant

amalgamation beneficiation process of gold CIP is a kind of gold beneficiation plant process for gold ore in a higher degree of oxidation Amalgamation Cylinder for Gold Extraction.

Gold Amalgamation - Mineral Processing & Metallurgy

In order to consider the gold amalgamation process intelligently, it was first necessary to learn the nature of an amalgam. In the performance of this task it was found necessary to consult a large volume of literature and to perform experimental investigations.

Small Gold Processing Plant - Mineral Processing & Metallurgy

Flotation in a Small Gold Processing Plant The ground pulp after jigging and amalgamation will usually contain 20 to 25% solids which is ideal for flotation feed. This pulp passes to a Conditioner where reagents are added to activate the sulphides and possible tarnished gold values.

Gold Mercury Amalgamation Methods

The mill in which the ores were treated consisted of two 800-lb. stamps, two amalgamating-plates, four pans, two automatic washers, two Frue vanners, and the necessary accessories for assaying, retorting and refining gold. The plant, originally erected with American capital, and directed by competent Americans, passed into the hands of Mexican owners.

gold amalgamation plant - elplaninicial.cl

Solar Power Plant Advantages Small Solar Panels For Sale Solar Power Plant Advantages Solar System Powerpoints What Solar Power System Do I Need. Inquire Now; Mineral Processing Mine Engineer.Com. information on gold, flotation, mineral processing, carbon in leach plants. Inquire Now # Solar Power Generation Plant Solar Electric Panels

Mercury Amalgamation - Mine Engineer.Com

Amalgamation is a concentrating process in which metallic gold or silver, or an alloy of the two, is mixed with mercury, either in a amalgamation drum, or on a amalgamation table, where the precious metal bonds with the mercury to form the metal laden mercury AMALGAM and the waste (barren) ore pulp are caused to travel different paths to effect separation.

Amalgamation: Using Mercury to capture fine gold, retort ...

Occasionally, the amalgamation process does not collect as much gold as anticipated. This type of result usually occurs when the formation of amalgam is inhibited due to poor contact between the gold and the mercury. This happens most commonly when the gold is very fine or when it …

Gold Mining Equipment | Gold Wash Plant for Sale - JXSC

This processing method is suitable for the quartz vein gold-bearing ore, gold-bearing altered rock type ore and sulfides ore which with fine gold particle and good floatability, widely applied in the medium-large good mining plant. 4. Gravity separation (amalgamation)-flotation process

extraction of gold by amalgamation plant

Amalgamation of gold amalgamation gold extraction process is an old China Supplier 5 Tons Small Scale Gold Processing Plant Gold Mining . but also for hard Get Price gold ore extraction plant cost

The Determination of Mercury in Synthetic Gypsum by ...

The remaining combustion products including elemental mercury (Hg0) are swept through a gold amalgamation trap where elemental Hg is trapped and concentrated. After the amalgamation step, the trap is heated to release the mercury into a carrier gas which transports it …

gold amalgamation process

Gold refinery Uganda by amalgamation process The purification of such alluvial gold alloys is a simple matter. The high specific gravity of the metal allows of separation from most admixed materials by some process of elutriation, or water concentration, or, in arid regions, by dry blowing.

Ball Mill|Mill Amalgamation Of Gold In Ball Mill

Ball Mills Amalgamation Namari Heavy Machinery. Ball mill amalgamator mining quarry plant the ball mill the crushed ore is now put into a ball mill amalgamation this is accomplished with mercury which absorbs gold new and used equipment for prospecting and mining for gold get a quote ball mill gold amalgamation miners add mercury to ore in ball mills during the milling process whole ore