M Sand Manufacturing Process - YouTube

01.02.2017 · M Sand is an economical alternative for River sand. It has zero wastages when compared to river sand, and costs 45 - 50% lesser than river sand.

Manufactured Sand (M-Sand) for Concrete …

Since manufactured sand (M-Sand) is processed from selected quality of granite, it has the balanced physical and stone properties for construction of concrete structures. This property of M-Sand helps the concrete structures withstand extreme environmental conditions and prevents the corrosion of reinforcement steel by reducing permeability, moisture ingress, freeze-thaw effect increasing ...

Quartz Stone Manufacturing Process: Everything …

The manufacturing process involves a mixture of quartz aggregated chips pigments, additives, and resin binders. Engineered quartz stone for slab and countertop applications come in a wide array of colors, textures, and patterns. Depending on the manufacturing process, the texture can be either coarse or fine. Then, it is possible to combine it with glass and any other reflective materials to ...

process of quartz sand manufacturing - Mine …

silica sand manufacturing process - YouTube 1 Oct 2012 ... Fascinating Silicone™ - ... Quartz Sand Process - Crusher Quartz Sand Process. Quartz sand production line. Quartzite is a decorative stone and may be used to cover walls, as roofing tiles, as flooring, and stair steps. SILICA The production increase for silica sand followed several years of increasing ..... can produce cultured ...

Quartz Sand Manufacturer Plant - cz-eu.eu

Quartz Sand Manufacturer Plant. silica sand manufacturing process - YouTube. Oct 01, 2012 · Fascinating Silicone™ - Manufacturing Silicone from Sand:solution.mineralsprocessingplant/ Silica Sand Process Making Plant,silica quartz processi.

The Pros and Cons of Manufactured Sand - The …

There are various factors that are currently driving the production of manufactured sand: Global scarcity for natural sand: Injudicious sand mining and continuous depletion of natural aggregate sources have led to the implementation of new environmental/land use legislations which has made the procurement of natural sand difficult and expensive. Sand dredging is heavily taxed/ banned in many ...

Silica Sand Processing & Sand Washing Plant …

Summary of the Silica Sand Processing Plant Equipment. In general most silica sands can be beneficiated to acceptable specifications by the flowsheet illustrated. Reagent cost for flotation is low, being in the order of 5 to 10 cents per ton of sand treated. If feldspars and mica must also be removed, reagent costs may approach a maximum of 50 cents per ton. Laboratory test work is advisable ...

Silica Sand Washing Plant | Quartz Sand …

22.02.2020 · Silica sand washing plant mainly includes: quartz stone crushing and sand making, washing, grading, desliming, scrubbing, magnetic separation, flotation, acid leaching and other processes to remove the small amount or micro amount of impurities in silica sand and obtain refined silica sand or high-purity silica sand for glass, ceramics, construction, stone and other industries.

Quartz Sand Production Line

Quartz Sand Production Line. Quartz sand refers to contain more river sand, sea sand, silica weathered sand, etc. Get Price And Support Online; quartz sand line production - rehabilitacja-wroclaw. It is a full set of quartz sand production line equipment produced and designed by which provides you with the comprehensive technical support. Get ...

Quartz Processing,Crushing & Grinding,Plant | …

The purity of quartz sand determines its value and application fields, and most processing is for removing the mineral impurities. So, the way to prevent new contamination during crushing and grinding process is also very important. Ceramic grinding system, stainless steel connecting parts, clean working environment and dedusting system are very helpful to minimize the emergence of new impurities.

MSAND - from Poabs (Manufactured Sand) - …

05.12.2013 · Manufactured sand production: Green Techniques - Duration: 3:03. CDE Asia 28,753 views. 3:03. ... Most Satisfying Manufacturing Process Never Seen Before - …

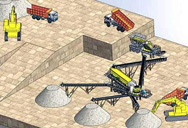

How to Start Sand Manufacturing Business - …

The manufacturing of the Sand process involves three stages. These are crushing of stones in to aggregates by VSI, then fed to Rotopactor to crush aggregates into the sand to required stone sizes (as fines). Then, do the screening to eliminate dust particles and Washing of sand eliminates very fine particles present within. Finally, the end product will satisfy all the requirements of IS:383 ...

Manufacturing Process of Quartz | Seattle Granite …

The manufacturing process of most quartz countertops begins with inspecting the raw materials for quality and homogeny, feeding them into a mixer, and blending them into a substance that resembles wet sand. The mixture is then poured into a mold, creating slabs which are then compacted with a special vacuum and vibration process with a pressure of 100 tons. This compacting is what makes ...

Manufacturing of Bricks | Method, Process, Types.

Stage 5. Cooling and Burning of bricks. Stage 1. Selection of the Suitable Type of stone Earth : Good quality building bricks can not be made from every type of earth or soil.As a general statement, it may be said that any soil (earth) which contains four parts of clay and one part of sand …

quartz sand mineral processing equipment 」

Quartz Sand Processing Plant Wholesale, Processing Plant . offers 322 quartz sand processing plant products. About 9% of these are crusher, 2% are mineral separator, and 1% are sand making machinery. Chat Online . Inquire Now; plant and machinery for mineral processing quartz. Alibaba offers 393 quartz sand processing plant products. About 11% of these are crusher, 1% are mineral …

Process For Manufacturing Silica Sand Powder 10 …

Process For Manufacturing Silica Sand Powder 10 Micron In India. Low grade iron ore benification plant manufacturers in india 250tph river stone crushing line in chile 200tph granite crushing line in cameroon 250tph limestone crushing line in kenya 250tph granite crushing line in south africa kefid 120tph granite crushing line in zimbabwe . Jaw Crusher. Great energy conservation, wide ...

Glass Bottle Manufacturing Process - Step by Step …

We are going to see Stepwise Glass bottle manufacturing process in this article. We use glass bottles in everyday life. Glass is a ceramic material. Glass bottles are manufactured by melting sand and blowing the molten viscous material into required shape using a mould and then cooled.

Sand Casting For Manufacture - Manufacturing …

Another advantage of sand to manufacture products by metal casting processes, is that sand is very resistant to elevated temperatures. In fact, sand casting is one of the few processes that can be used for metals with high melting temperatures such as steels, nickel, and titanium. Usually sand used to manufacture a mold for the casting process is held together by a mixture of water and clay. A ...