Raw Mill In Cement Plant,Cement Making Plant

This stone mainly introduces the raw mill in cement plant. In order to achieve the desired setting qualities in the finished product, a quantity (2-8%, but typically 5%) of calcium sulfate (usually gypsum or anhydrite) is added to the clinker and the mixture is finely ground to form the finished cement powder. This is achieved in a cement raw mill. The grinding process is controlled to obtain ...

Raw mill in cement plant photo - ontwerpbureau …

Raw mill in cement plant photo. Holcim Ste Genevieve Cement Plant The new cement manufacturing facility of Holcim US at Ste and the supply for the main processing equipment for this new giant plant Crushed lilimingne and clay is grinded and dried by vertical roller mills raw material require more than normal gas flow quantities through the mill for drying

Raw Mill for Cement Plant - Fote Machinery(FTM)

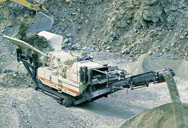

It has large application such as raw mill in cement plant, building materials, metallurgy, electric power and stone industry, which is mainly used for the grinding as well as drying of cement raw materials and other materials. When the raw material is crushed, it will enter the tube mill. With the movement and extrusion of steel balls, it will be ground into fine powder. The raw mill ...

Cement mill - Wikipedia

A cement mill (or finish mill in North American usage) ... These have been used for many years for the less exacting raw-milling process, but recently roller mills, in combination with high-efficiency separators, have been used for cement grinding. The grinding action employs much greater stress on the material than in a ball mill, and is therefore more efficient. Energy consumption is ...

raw mill in cement plant photo in ultratech at jaipur

Ball mill has been widely used for cement grinding. ..... working in hindi · raw mill in cement plant photo in ultratech at jaipur · raw mill in cement plant animations ... ACE 17th Annual Report (2010-11) - ACE Cranes 21 Sep 2011 ...

Raw Mill,Raw Mill In Cement Plant

13 Zeilen · Raw Mill Is Widely Used In Cement Plant. Raw mill is the key equipment for secondary …

Cement Production: Raw Meal Production in Steps

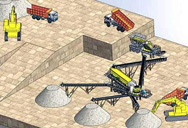

Cement Production: Raw Meal Production in Steps Perfectly mixed, accurately fed without pulsation, and precisely weighed. The key word is quality! And this quality is achieved during cement production with exactly matched process steps. In the first stage, the raw meal is produced, as described below.

Cement Raw Material | Loesche

Sohag – LOESCHE is involved in the new construction of a large cement plant in Egypt with three vertical roller mills. The end customer is the Egyptian Cement for Cement Projects Management S.A.E. The planned new plant is located nearly 500 km south of Cairo in Sohag. The LOESCHE scope of delivery includes a raw material mill with a capacity of 540 t/h of cement raw meal, a cement mill …

Raw Material Preparation - Cement Plants and …

From the early 1900s, both for cement grinding and for grinding hard raw materials, whether by wet or dry process, the standard arrangement was a ball mill for preliminary grinding (to below 0.75 mm), followed by a tube mill for fine grinding. Typically the ball mill was placed on an upper floor so that material could move by gravity. An example was the original rawmill system at

Spe Hammer Cutter Mill Price Quarry Plant And …

Raw material: all kinds of ores, cement, silicate product, building material , refractory material, fertilizer and ceramics. Get Price List. Latest Products. Our Solutions. Message. If you have any suggestions or question for us.Please contact us. Glen Creston Swing Hammer Mill Nivellesswimming. Glen creston stanmore tabletop hammer mill wikipedia. 24 ResultsThe Glen Creston Swing Hammer mill ...

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL …

cement plant. The stone also describes the principle of the mill load control system developed by the Holderbank Engineering Canada Limited (HEC), Canada for the optimisation of the performance of the ball mills for obtaining maximum production and minimum specific energy consumption. 1. INTRODUCTION The need for process optimisation through diagnostic studies has been increasingly …

cement raw mill - Deutsch-Übersetzung – Linguee Wörterbuch

Viele übersetzte Beispielsätze mit "cement raw mill" – Deutsch-Englisch Wörterbuch und Suchmaschine für Millionen von Deutsch-Übersetzungen.

cement mill plant - bierzelt-2011.de

Cement Production Line - cement plant,ball mill,vertical . In the cement production line, producing 1 ton of Cement need grind at least 3 tons of materials (including raw materials, fuel, clinker, mixed materials,gypsum).Grinding operation consumes about 60% of total power in cement plants, raw material grinding more than 30%, while coal mill used in cement plant consumes 3%, cement …

How To Calculate Effective Surface Of Raw Mill In …

Raw Mill In Cement Plant,Cement Making Plant. The cement is delivered to end-users either in bags or as bulk powder blown from a pressure vehicle into the customers silo. In industrial countries, 80% or more of cement is delivered in bulk. Our raw mill has been widely used in the cement making plant. Effective Optimization of the Control System for the . Dynamics in raw meal production ...