The Working Principle Of A Jaw Crusher - Editors Top

Powered by a diesel or gas motor, the jaw crusher brakes materials in a crushing chamber. The materials are pushed inside the chamber from the top opening and when crushed they are released through the bottom opening. The crushing power of the jaw crushers …

Crusher - Wikipedia

A jaw or toggle crusher consists of a set of vertical jaws, one jaw is kept stationary and is called a fixed jaw while the other jaw called a swing jaw, moves back and forth relative to it, by a cam or pitman mechanism, acting like a class II lever or a nutcracker. The volume or cavity between the two jaws is called the crushing chamber.

Jaw Crusher Maintenance Of Technical Standards

Home > Jaw Crusher Maintenance Of Technical Standards PE Jaw Crusher PE series jaw crusher is usually used as primary crusher in quarry production lines, mineral ore crushing plants and powder …

Jaw Crusher Components & Parts

Although the jaws do the work, the real heart of the jaw crusher and its components are the toggle plates, the pitman, and the ply wheel. These are the parts and components that generate the crushing action …

Jaw Crusher Single Toggle Grease Base

Established in the 1986, we, K. V. Metal Works, an ISO 18001 : 2007 Certified company for Quality Management System, are engaged in Manufacturing and Supplying superior quality Industrial Crusher and Vibrating Screen.Our product range includes Single Toggle Stone Crusher, Single Toggle Jaw Crusher, Double Toggle Oil based Stone Crusher, Double Toggle Grease based Stone Crusher…

Jaw Crushers - MEKA Crushing & Screening Plants

Jaw crushers reduce large rocks or ore by means of compression. Mechanical pressure is applied using the crusher’s two jaws; one is fixed while the other reciprocates. There are also primary and secondary types of these crushers.

Jaw crushers - liming

Jaw crushers are a popular alternative to primary gyratory crushers, since they can process large amounts of hard material efficiently. For 45 years, liming C Series jaw crushers have proven their reliability in different primary crushing operations in aggregates, mining and recycling applications, with up to 11,000 jaw crusher …

Jaw Crusher Machine - YouTube

Nov 22, 2013 · YONG WON JAW CRUSHERS IN THE QUARRY SITES - Duration: 4:54. YONGWON KOREA 533,345 views. 4:54. Stone Crusher Working - Propel - Jaw crusher …

Jaw Crushers for sale | eBay

Purchasing Jaw Crusher Machines on eBay: a Guide. Whether youre just getting into the business of mining or are looking for an upgrade, a jaw crusher is an industry must-have. Designed for crushing rock to be made into concrete, asphalt, and similar materials, a high-quality jaw crusher …

Jaw Crushers | McLanahan

A Jaw Crusher uses compressive force for breaking material. This mechanical pressure is achieved by the crushers two jaws dies, one of which is stationary and the other is movable. These two vertical manganese jaw …

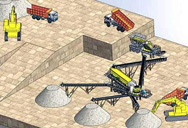

SAND, GRAVEL, AND CRUSHED STONE ON-THE-JOB …

JAW CRUSHER The jaw crusher squeezes rock between two surfaces, one of which opens and c loses like a jaw. Rock enters the jaw crusher from the top. Pieces of rock, that are larger than the opening at the bottom of the jaw, lodg e bet ween t he tw o metal plates of the jaw.

crusher plant administration - boekhandeldekorf.nl

Wesley J Sherwood Jr crusher feed controller age 22 was killed on Dec 15 2011 when he fell into an operating jaw crusher according to a report from Mine Safety and Health Administration MSHA Sherwood …

NW80™ portable jaw crusher - liming

The liming NW Series™ NW80 portable jaw crusher plant is the most compact portable plant from the NW series. The wheel-mounted and electrically powered unit is equipped with a liming® C80™ jaw crusher with up to 90 kW of crushing power. The C80™ belongs to the liming® C series™ jaw crusher product family.The crushers …

P&Q University Lesson 7- Crushing & Secondary Breaking ...

Sep 02, 2019 · Jaw crushers are also compression crushers that allow stone into an opening at the top of the crusher, between two jaws. One jaw is stationary while the other is moveable. The gap between the jaws becomes narrower farther down into the crusher.

MSHA - Metal and Nonmetal Mine Fatal Accident ...

Jaw Crusher The jaw crusher was a model 3042 manufactured by Cedar Rapids. The jaw width was 42 inches. The crusher was powered by a 325 horsepower Caterpillar diesel engine through a clutch …