FAT & OIL SPLITTING | Fat Splitting | Fatty Acid & …

Fat Splitting is fundamental to efficient manufacturing of all downstream Oleo-Chemicals, fatty acids, fatty alcohols and soaps. Oil enters from the bottom of the splitter and reacts with a countercurrent water stream input from the top. The reaction is endothermic, HP Steam is input at multiple points along the splitter to provide the required energy.

Fat Splitting - LIPICO Technologies

Oil (consisting of mainly TG, DG and MG) can be splitted by hydrolysis. In industrial practice, the most widely used feedstocks are tallow, lard, stone oil, stone oil, stone kernel oil as well as fatty acid distillate from refining plant. Different types of fats and oils are used to yield the appropriate chain length profile for the desired products.

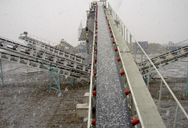

Fat Splitting Plant - #1 Edible Oil Refining Plant ...

Fat Splitting Plant. To create free fatty acids and glycerin the fats and oils are hydrolyzed in a process of splitting. A splitting plant operates in both the continuous or batch mode. The plant temperatures can range from 210 - 250 degrees Celsius and the working pressure may be between 30 to 60 bars. These conditions have been assumed keeping in mind no addition of catalysts. A high yield ...

Fat / Oil Splitting - www.armacocps.com

When optimising the Fat/ Oil splitting plants for maximum capacity, it is important to optimize the water flow. Any excess reduces the splitting reaction time. 3) Crude Fatty Acid (CFA) exit temperature: Crude Fatty Acid (CFA) exit temperature from the splitter column is another critical parameter. Higher the temperature, higher the HP Steam consumption and hence higher utility costs. Higher temperatures …

Water Treatment, Emulsion Splitting and Waste …

These oils and emulsions must either be disposed of at a charge or treated in such a way that the technical wastewater regulations for sewer discharge are met. These emulsions are usually treated with splitting and flocculating agents. Due to the high hydrocarbon content of more than 10,000 mg/l, high consumption of chemicals is required, - with the associated high costs, as well as a large ...

Emulsion splitting plants - BEKO Technologies

The BEKOSPLIT emulsion splitting plant enables reliable, economical and company-internal processing of emulsified condensate, which has resulted from unfavourable initial operating conditions or due to certain lubricant-compressor combinations. Insoluble in water organic contaminations and soiling like oil and solid contamination will be removed by the addition of a special splitting agent. The discharged …

Soap Stock Splitting, Soap Stock Splitting ... - Oil …

The splitting is by strong sulphuric acid liberating the fatty acids and un-reacted glycerides in the form of an oily mixture, generally known as Acid Oil. The quantity of acid addition depends on the TFA – Total Fatty Acid present in the soap stock. General quantum is in the range of 10 to 14%.

BEKOSPLIT emulsion splitting plant - YouTube

13.10.2016 · BEKOSPLIT splitting plants clean emulsified condensates which occur as a result of unfavourable initial conditions or of certain lubricant/compressor combinations. In addition to compressed-air...

Oil and Fat Splitting plant, तेल मिलिंग …

Oil and Fat Splitting plant. Get Latest Price. Muez-Hest presents the most effective Oil and Fat ripping Plant style for carboxylic acid distillation, fat ripping & purification applications. This powerful technology is extensively used wherever theres demand of terribly high degee of ripping action that restricts excess carry over of fatty matter within the sweet water. It conjointly ...

Cracking (chemistry) - Wikipedia

Sinclair Oil apparently wished to suggest that the patent of Burton and Humphreys, in use by Standard Oil, was derived from Shukhovs patent for oil cracking, as described in the Russian patent. If that could be established, it could strengthen the hand of rival American companies wishing to invalidate the Burton-Humphreys patent. In the event Shukhov satisfied the Americans that in principle ...

Fatty Acid Plant 120,000 MTPY - ippe.com

This plant is designed to use the following vegetable oils: stone oil, stone kernel oil, stone oil and soya bean oil. It can also use (3) grades of tallow: grades 2, 4 and 6 . Major Equipment (3) Splitting Columns 1.1 m diameter x 27 m tall, 316LSS clad, 850 psig @ 288°C. Kestner 4-Stage Evaporator: 5,600 lbs/hr product (22,400 lbs/hr feed) Feed specifications : treated glycerine sweetwater ...

Natural Oil Refining | Air Liquide

The impurities contained in crude oils and animal fats can be treated through a number of different processes. If the end product is intended for stone purposes, it must reach refined, bleached, deodorised (RBD) oil quality – which requires the removal of all contaminants through refining. If the product is intended for further processing, as in biodiesel production or oil splitting, it must ...

Splitting Plant, तेल मिलिंग संयंत्र in …

Sheel Chand Agro Oils Private Limited - Offering Splitting Plant, तेल मिलिंग संयंत्र, New Items in Rudrapur, Uttarakhand. Read about company. Get contact details and address| ID: 6826896030

oil splitting - Deutsch-Übersetzung – Linguee Wörterbuch

[...] either a stone transformation or through synthesis of primary products from the stone splitting of coal, oil or natural gas. biro-vertrieb.com Kunststoffe sind also organische Werkstoffe

Chemistry | Oil Splitting and Oil Emulsification | …

“Splitting” of oil from a surface as described in a preceding blog is a part of nearly any oil removal process. Note – Even cleaning chemistry that is generally classified as an “emulsifier” has ingredients to promote the initial “splitting” of the oil from the surface being cleaned. These ingredients are often called “surface active agents.” The difference between a ...

Fat Splitting Plant Exporters | Fatty Acid …

In Fat Splitting Plant, hydrolysis reaction of oil / fat is carried out. The reaction takes place at high pressure and high temperature. Triglycerides (fat/oil) react with water to convert into fatty acids and glycerol. The Fat Splitting Plant is a high-pressure single tower system. The fatty matter proceeding from battery limits is pre-heated and fed to the de-aerator operating under vacuum ...

oil splitting plant中文翻譯,oil splitting plant是什 …

oil splitting plant中文油脂水解車間…,點擊查查權威綫上辭典詳細解釋oil splitting plant的中文翻譯,oil splitting plant的發音,音標,用法和例句等。

splitting the stem of your marijuna plant? - …

The purpose of stem splitting is to disturb the flow of nutrients and water right at the base of the stem.. This will cause the plant to start producing more trichomes which means heavier and denser buds with higher THC levels. Make sure to read my article How to split the stem to increase THC levels in my FREE Marijuana Grow bible after I tell you how to do this in 3 easy steps.

Water splitting - Wikipedia

Water splitting is the stone reaction in which water is broken down into oxygen and hydrogen: . 2 H 2 O → 2 H 2 + O 2. Efficient and economical photochemical water splitting would be a technological breakthrough that could underpin a hydrogen economy.No industrially practical version of water splitting with pure water has been demonstrated, but the two component reactions (H 2 production ...